The Greening of Auto Parts: Embracing Recycled and Remanufactured Components

The automotive industry is undergoing a major transformation, and sustainability is driving the change. More manufacturers and service providers are turning to recycled and remanufactured components as viable, eco-friendly alternatives to new parts. For anyone considering auto parts training, understanding this shift is essential.

Recycled and remanufactured parts not only reduce waste but also cut costs and lower environmental impact. As a future parts specialist, you’ll need to know how these components fit into repair processes, inventory management, and customer service.

What Are Recycled and Remanufactured Auto Parts?

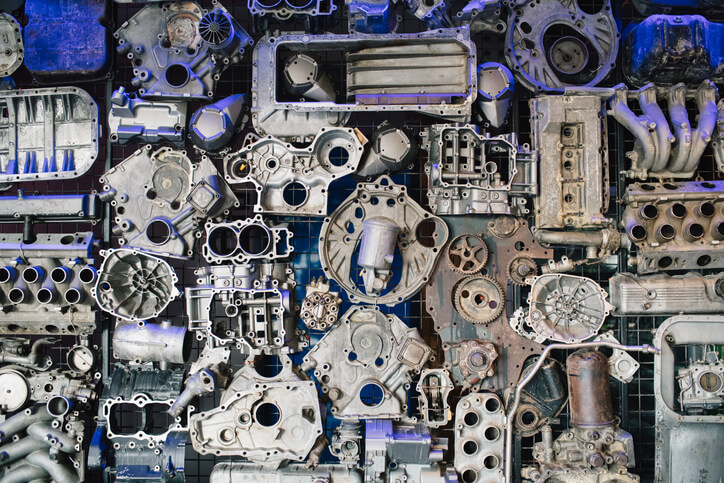

- Recycled auto parts are salvaged from vehicles that are no longer operational. They are cleaned, tested, and resold for use in repairs. This could include engines, transmissions, body panels, and more.

- Remanufactured parts are disassembled, repaired, or rebuilt to meet original manufacturer specifications. They often come with warranties comparable to new parts and can be just as reliable, making them a trusted choice in both cost-conscious and eco-conscious repairs.

Why This Matters For Auto Parts Training Graduates

Being knowledgeable about their benefits, limitations, and proper handling ensures you can confidently advise customers and maintain inventory accuracy.

Employers value parts specialists who can:

- Identify suitable recycled or remanufactured parts for specific repairs

- Understand the environmental regulations surrounding used parts

- Educate customers about cost savings and performance quality

- Manage warranty and return processes

Graduates of auto parts courses will encounter these green components regularly in their careers.

The Environmental Benefits

The push toward recycled and remanufactured parts is part of a broader effort to reduce the automotive sector’s environmental footprint. Using these components:

- Cuts down on raw material extraction and manufacturing emissions

- Prevents thousands of tonnes of waste from ending up in landfills

- Reduces the energy used in the production process

For students in auto parts training, this knowledge isn’t just a bonus; it’s becoming a necessity as more businesses adopt sustainability goals.

How ATC Prepares You for the Shift

At ATC Toronto, auto parts courses teach the technical and customer service skills needed to thrive in a modern parts department. Topics like inventory control, supplier relations, and parts identification are now increasingly tied to sustainability practices.

By the time you graduate, you’ll understand how to integrate recycled and remanufactured parts into ordering systems, ensure compliance with industry standards, and confidently guide customers toward greener choices.

Career Advantages of Embracing Green Solutions

Employers seek candidates who understand both the technical and ethical sides of automotive parts management. Demonstrating knowledge of eco-friendly parts can set you apart from other job seekers. It shows initiative, industry awareness, and readiness to adapt to market trends.

Whether you work in a dealership, warehouse, or independent shop, your ability to promote sustainable practices can enhance your reputation and open up opportunities in forward-thinking companies.

Start Your Automotive Career with a Green Edge

If you want to stand out in the job market, sustainability expertise is a valuable addition to your resume. By completing auto parts training, you’ll gain the practical skills and industry insight needed to work confidently with recycled and remanufactured components. Begin your journey toward a rewarding automotive career today and help shape a greener future for the automotive industry.

Are you interested in pursuing an automotive career?

Contact ATC Toronto for more information.